Urban Rigger

哥本哈根,丹麦

680 平方米

住宅

2016 年

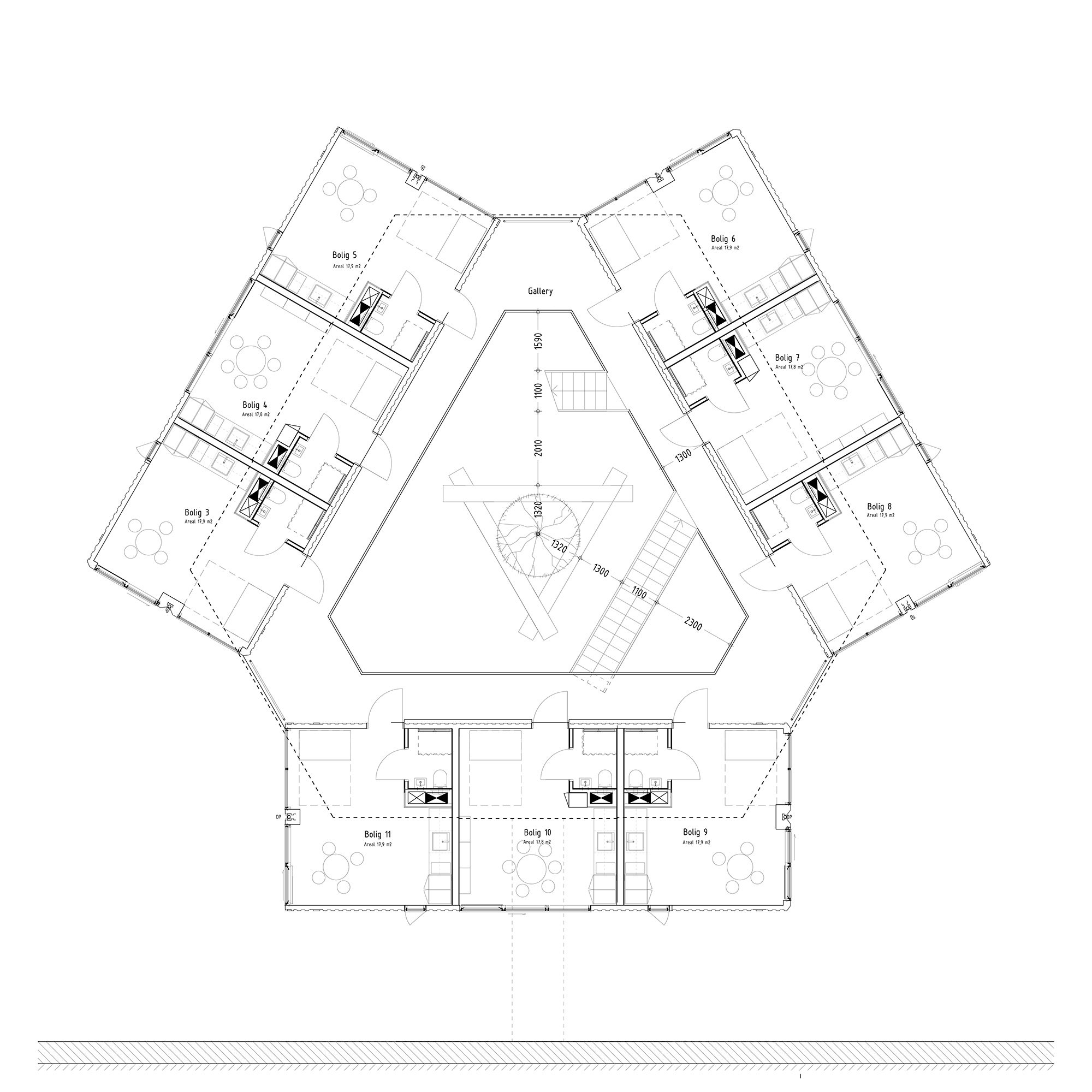

哥本哈根的港口仍然是城市中心未充分利用和欠发达的地区。通过引入针对港口城市优化的建筑类型,我们可以引入一种让学生住在市中心的住房解决方案。标准化的集装箱系统已经开发出来,允许货物以非常低的成本在复杂的运营商网络中运输到世界任何地方。通过使用标准集装箱系统,我们提供了极其灵活的建筑类型学框架。十二个学生宿舍以六边形堆叠九个集装箱单元,构成一个公共庭院,并位于共享浮桥的顶部。由此产生的房屋享有海滨景观,并可直接通往哥本哈根的干净水域,因此居民可以跳出窗户游泳。每个漂浮的集体就像一个微小的人造生态系统:一个热泵从海港水中抽取所有用于淋浴和取暖的热水,其中一个容器顶部的光伏电池板为学生和他们的家提供电力。除了量产,Urban Rigger 住宅还具有浮力和移动性的优势。如果哥本哈根的情况发生变化,这些单元很容易分离,可以被拖到镇上的下一个城市开发区——一群可部署的房屋,随时准备着锚并暂时占领下一个边境。

版权声明:未经授权,不得转发。

所属专题

-

最多产的建筑师一生中可能会实现 100 座,最多 1000 座建筑。每年在全球范围内上升的数十亿平方米的沧海一粟。无法扩展,即使在生产力的上限,建筑仍然是精品。如果我们看看过去 30 年美国制造业生产力的提高,每个工人创造的价值增长超过 150%。在建筑方面,我们看到一条平缓的下降线。主要区别在于,建筑行业几乎没有受到流经制造业的自动化浪潮的影响。尽管该行业明显缺乏创新,但每座建筑都是原型——总是从头开始。对原创的坚持是原创建筑最大的阻碍。通过从不重复设计,我们消除了我们在制造中发现的改进和优化的力量;例如,即使设计类型保持不变,iPhone X 也远远优于 iPhone 1。

通过产品化建筑,我们可以提供大规模的建筑影响。我们可以将建筑简化为家具的规模——将建筑简化为产品,预制建筑直接通过卡车运送且功能齐全。或者我们可以设计制造的元素,比如乐高的建筑等价物,这使得它们的重新组装几乎可以无限变化。我们可以创建经典的原始建筑原型,并将其重新部署到世界各地的多个城市,由于地理分离,它们的独特性完好无损。最后,通过摆脱建筑的最大优势和弱点——它与房地产、固定资产的内在联系——我们可以将建筑和城市想象成产品。从陆地和重力中解放出来,漂浮在水面上,可以像一群等待停靠一年、十年或一个世纪的预制社区一样展开。建筑师的想法很丰富,但影响力往往很差。无行动的想法。没有使命的愿景。产品化可以释放制造在建筑上的力量,以产生大规模的影响,最终融合两全其美:大量定制的可持续设计,高质量和低成本。原为新标准。The most prolific architect will realize maybe 100, at best 1,000, buildings in a lifetime. A drop in the ocean of the billions of square meters that go up all over the planet every year. Unable to scale, architecture remains boutique even at its upper limits of productivitv. If we look at the increase in productivity in American manufacturing over the last three decades, the increase in value generated per worker is more than 150 percent. For construction, we see a flat line with a gentle decline. The main difference is that the construction industry has remained practically unaffected by the wave of automation that has flowed through manufacturing. And despite the apparent lack of innovation in the industry, each building is a prototype-always starting from scratch. The insistence on the original is the greatest hindrance for original architecture. By never repeating a design, we eliminate the forces of refinement and optimization that we find in manufacturing; the iPhone X, for example, is vastly superior to the iPhone 1 even if the design typology has remained the same.

By productizing architecture, we can deliver architectural impact at scale. We can reduce the architecture to the scale of furniture - a building to a product, prefabricated and fully functional straight of the truck. Or we can design manufactured elements, like the architectural equivalent of LEGO, which allow for almost infinite variability in their reassembly. We can create the classic original architectural prototype, and redeploy it in multiple cities across the world, their uniqueness intact due to geographical separation. Finally, by freeing ourselves from the greatest strength and weakness of architecture - its intrinsic connection to real estate, fixed assets-we may be able to imagine buildings and cities like products. Liberated from terra firma and gravity, floating on water, deployable like a fleet of prefabricated neighborhoods waiting to dock for a year, a decade, or a century. Architects are rich in ideas, but often poor in impact. Thoughts without action. Vision without mission. Productization can unleash the power of manufacturing on architecture to deliver impact at scale, finally merging the best of both worlds: custom-tailored sustainable design at great numbers, high quality at low cost. The original as the new standard.